More info on BJC2100 Attempt

My first attempt at creating a functional printer was with the Canon Bubble Jet (BJC) 2100. This printer was chosen because it had been shown to be successful in printing biological samples by Thomas Boland et al. (2003). By modifying the stripping the printer of its cover and extraneous parts and by remounting the mechanism on which the printer stood, the Boland group was able to create a new platform on which to print. In order to pass cells through the actual cartridge, they simply opened the printer cartridge, rinsed it thoroughly with ethanol, and refilled it with their cell solution. In order to ensure that the cells were alive after they passed through the cartridge, the group was able to modify the printer drivers to apply less current across the individual heaters, thereby reducing the temperatures experienced by the cell and theoretically increasing overall viability.

I chose to use the BJC 2100 because of the previous successes, as well as the simplicity of the printer mechanism. Many printers today are combination machines (i.e., include fax and scanning) or incorporate more advanced and complicated paper feeding mechanisms. Because the BJC2100 model was first debuted over 12 years ago, the mechanism is relatively simple, with only one principle advancement gear system. I believed this would make it easier to separate out different components of the device and alter the over all functioning of the system.

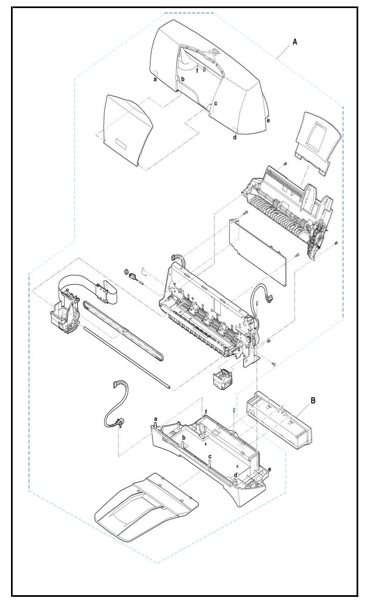

Exploded view of the BJC printer

I first disassembled the mechanism, removing the covers and extra paper feed trays. After removing the key printer device from the base, I remounted the printer track on new mounts cut from scrap ABS sheets. However, once I examined the paper advancement mechanism, I realized that the printer head and feeder mechanisms were already coupled in an ideal orientation and activation cycle; I figured that the alternating motion between the printer deposition and the paper advancement should be utilized instead of remaking the whole system. Additionally, stepper motors and compatible stages were all occupied within the 20.345 lab. Therefore, I decided to shift from moving the printer head forward over a stationary sample to moving the sample under a stationary printer head track.

A huge draw of this printer was the claimed availability of the printer drivers. However, after calling Canon technical support multiple times, I was unable to obtain the driver code from the manufacturers. Examination of driver code from other printers led to the conclusion that modifications would involve back-engineering the system from the core library (DLL) files, an extremely complicated and tedious process. Furthermore, talking to Thomas Boland led me to believe that their lab has since discovered that driver modification has a minimal effect on the actual efficacy of the printer. Therefore, I established that driver modification may not be the best option for my project.

Since one of the primary reasons behind choosing the BJC2100 was to access the drivers and that had not panned out, I saw no clear reason why not to switch to another platform that was more modern and could more easily sync to a Mac OS.