Inkjet Technologies

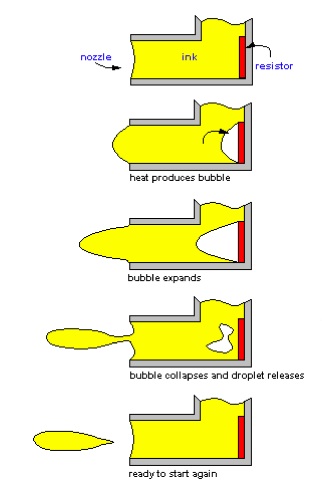

Inkjet printing technology was first developed in the 1950s and gained popularity when, in the 1970s, inkjet printers were developed to reproduce digital, computer-generated images. Today, most consumer inkjet printers from companies, such as Canon or HP, utilize thermal drop-on-demand (DOD) technologies. Print cartridges have a series of 300-600 tiny nozzle chambers, each containing a heater. To form a drop, a pulse of current passes through the chamber and forms a bubble. The bubble isolates a small quantity of the ink, which forces the droplet out onto a piece of paper. As the droplet is expelled, the surface tension of the ink helps pull another tiny aliquot of ink into the chamber from the main body of the ink cartridge.

Inks in thermal DOD printing are mixtures of water with glycol and dyes, since thermal inkjet heads typically require aqueous solutions for the current to have the proper effect. Since neither the ink nor the printer head require special materials, inkjet technologies are inexpensive, thus their consumer appeal.

Many other inkjet printing technologies exist and are widely used today. Piezoelectric DOD utilizes a piezoelectric material instead of a heating element. When a voltage causes the material to change shape, a drop is forced out of the printing nozzle. With a long service life and low operating costs, this form of inkjet printing is often used in commercial production lines, most commonly to mark expiration dates on perishable products. Alternatively, continuous inkjet printing subjects drops to an electrostatic field and directs them via electrostatic deflection to print onto the surface. The high velocity of droplets allows for quick printing and for greater distances between printer head and the printing surface. Despite the potential appeal of these additional methods, this project focuses mainly on thermal DOD inkjet printing.