Difference between revisions of "Optical trap"

(→Finding α) |

(→Finding α) |

||

| Line 31: | Line 31: | ||

<table class="wikitable" style="text-align:center"> | <table class="wikitable" style="text-align:center"> | ||

| − | <caption style="font-size:14pt">Trap stiffness calibration methods and sensitivity to measurement | + | <caption style="font-size:14pt">Trap stiffness calibration methods and sensitivity to measurement parameters</caption> |

<tr> | <tr> | ||

<th scope="col" rowspan="2">Method</th> | <th scope="col" rowspan="2">Method</th> | ||

Revision as of 16:20, 26 March 2013

Introduction

Optical tweezers can exert and measure forces on micron-scale dielectric particles. This capability offers a unique and valuable tool for manipulating and measuring cell components at the single molecule level. For example, optical traps have been used extensively to investigate the mechanical properties of biological polymers and the force generation mechanisms of molecular motors. In many studies, optical tweezers apply force to functionalized microspheres, which act as convenient handles attached to molecules of interest.

To make quantitative force measurements, the instrument records the displacement of a trapped microsphere over time. For small displacements, the exerted force is very nearly proportional to displacement, so the trap can be modeled as a linear spring. Accurate force and position measurements depend on careful calibration of the position detector responsivity, G, and the trap stiffness α, also called the spring constant. The stiffness is a function of trapping laser power, bead size, bead composition, and optical properties of the sample.

This page has tips for setting up and aligning an optical trap. It discusses three methods for obtaining the spring constant and two methods for measuring α.

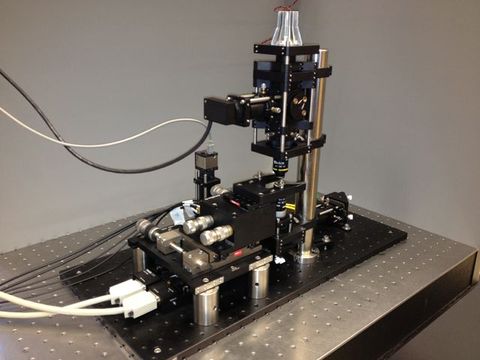

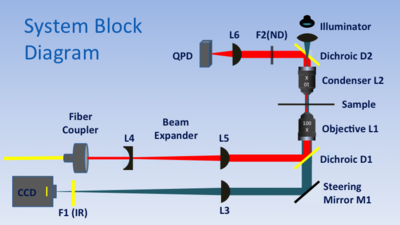

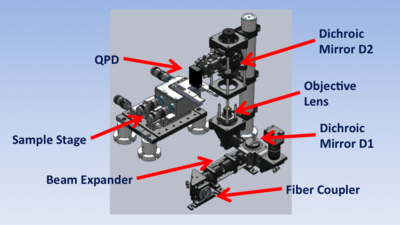

Instrument overview

A high-NA objective lens (L1) performs the dual functions of imaging the sample and focusing the trapping laser. L1 is a 1.25 NA, 100X, infinity corrected, oil immersion objective lens with a working distance of 0.65 mm. Its back aperture is 5mm in diameter.

L7 focuses an image of the LED illuminator in the backplane of the condenser lens L2 to provide collimated transillumination in the sample plane. L2 is a .25 NA, 10X, infinity corrected objective lens with a 7 mm working distance. Steering mirror M1 and tube lens L3 complete the imaging path. L3 is a 1" diameter, uncoated plano convex lens with a focal length of 200 mm. L3 forms an image of the sample plane on the detector of a CCD camera placed at a distance of 200 mm. (For best performance, the distance between L3 and the CCD imager must be accurate.)

The trapping laser beam emerges from a fiber coupler with a diameter of approximately ??mm. Lenses L4 and L5 (focal lengths ?? and ??, respectively) implement a Galilean telescope that expands the beam by a factor of 4. To minimize aberrations and reflections, L4 and L5 are IR-coated achromatic doublet lenses. Dichroic mirror D1 deflects the collimated trapping beam toward L1.

Calibration

To make quantitative force measurements, the optical trap records the displacement of a trapped particle over time. For small displacements, the exerted force is very nearly proportional to displacement. In this range, the trap can be modeled as a linear spring. Accurate force and position measurements depend on careful calibration of the position detector responsivity, GQPD, and the trap stiffness α. GQPD and α are functions of the adjustment of the instrument, trapping laser power, bead size, bead composition, and optical properties of the sample. The instrument has to be calibrated for each type of sample and any time an adjustment is made. (Calibration can be sensitive to the angle of the sample chamber, so it is a good idea to recalibrate every time the sample is changed.)

Finding α

Several methods for measuring trap stiffness have been developed. Because the methods rely on different underlying principles, they tend to be sensitive to different types of experimental errors. Using multiple calibration methods can provide an important check on results.

The three methods are summarized in the following table.

| Method | Equation | QPD Responsivity | Stage Responsivity | Solvent Viscosity | Particle Diameter | Temperature | Technical Noise |

|---|---|---|---|---|---|---|---|

| $ R_{QPD} $ | $ R_{stage} $ | $ \eta $ | $ d $ | $ T $ | |||

| Equipartition | $ \frac{K_B T}{\langle R_{qpd} V_{qpd} \rangle ^ 2} $ | inverse square | none | none | none | linear and indirect (viscosity change) | systematic decrease |

| PSD | $ \left. {6 \pi^2 \eta d \, f_0} \right. $ | none | none | linear | linear | indirect (viscosity change) | small |

| Stokes | $ \langle \frac{3 \pi \eta d \, R_{stage} \, ^{d V_{stage}} / _{dt}} {R_{qpd} V_{qpd}} \rangle $ | inverse | linear | linear | linear | indirect (viscosity change) | none |

Finding GQPD

Similarly, there are several ways to measure GQPD — each with its own strengths and weaknesses.

Setup and alignment

Connecting the electronics

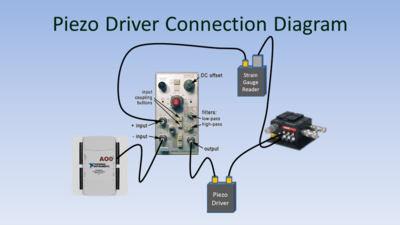

Some optical trap measurements (such as Stokes calibration, DNA tether measurement, and force clamping) require precise, computer-controlled movement of the sample. The Nanomax stage that holds the sample includes piezoelectric elements that can translate the sample over a range of approximately 20 microns in the X, Y, and Z directions. To control the position, a piezo driver applies a voltage across the piezoelectric element. The driver is part of a closed-loop system that also includes a strain gauge displacement sensor. The sensor generates a feedback signal that varies linearly with the stage position.

The piezo driver can be controlled directly by computer; however, it cannot produce the smooth, complex motions needed for some measurements. Accordingly, an alternate scheme is used to facilitate precise computer control of the stage position. The stage is controlled by a software-generated offset signal from a digital-to-analog converter connected to the computer. A differential instrumentation amplifier with unity gain is inserted in the piezo driver's control loop. The amplifier subtracts a the software-generated offset from the strain gauge reader's output. In response to a change in the offset voltage, the piezo controller adjusts the stage position until the set point is reestablished. The responsivity of the strain gauge reader is about 0.45 Volts per micron. Thus, a one volt change in the offset voltage produced by the DAC results in a movement of about 2.2 microns.

The offset scheme is implemented on the X and Y axes only.

<html>

|

<script type="text/javascript" src="http://html5.kaltura.org/js"></script> <script type="text/javascript"> mw.setConfig('EmbedPlayer.AttributionButton',false);

mw.setConfig('EmbedPlayer.EnableOptionsMenu',false);

</script> <object name="ttvplayer" id="ttvplayer" type="application/x-shockwave-flash" allowScriptAccess="always" allowNetworking="all" allowFullScreen="true" height="336" width="544" data="http://www.kaltura.com/index.php/kwidget/wid/_203822/uiconf_id/1898102/entry_id/1_tojxf237/"><param name="allowScriptAccess" value="always" /><param name="allowNetworking" value="all" /><param name="allowFullScreen" value="true" /><param name="bgcolor" value="#000000" /><param name="movie" value="http://www.kaltura.com/index.php/kwidget/wid/_203822/uiconf_id/1898102/entry_id/1_tojxf237/"/><param name="flashVars" value="autoPlay=false&streamerType=rtmp"/><a href="http://ttv.mit.edu">MIT Tech TV</a></object> |

|

Caption

|

</html>

--- say something about QPD ----

Remove the optics

Collimating and adjusting the fiber port

Initial laser alignment

Beam expander coarse adjustment

Condenser adjustment

Connecting the piezo stage

Fine adjusting the beam expander

<html> <script type="text/javascript" src="http://html5.kaltura.org/js"></script> <script type="text/javascript">

mw.setConfig('EmbedPlayer.AttributionButton',false);

mw.setConfig('EmbedPlayer.EnableOptionsMenu',false);

</script> <object name="ttvplayer" id="ttvplayer" type="application/x-shockwave-flash" allowScriptAccess="always" allowNetworking="all" allowFullScreen="true" height="336" width="544" data="http://www.kaltura.com/index.php/kwidget/wid/_203822/uiconf_id/1898102/entry_id/1_tojxf237/"><param name="allowScriptAccess" value="always" /><param name="allowNetworking" value="all" /><param name="allowFullScreen" value="true" /><param name="bgcolor" value="#000000" /><param name="movie" value="http://www.kaltura.com/index.php/kwidget/wid/_203822/uiconf_id/1898102/entry_id/1_tojxf237/"/><param name="flashVars" value="autoPlay=false&streamerType=rtmp"/><a href="http://ttv.mit.edu">MIT Tech TV</a></object>

</html>

OTKB software

Starting the software

<html> <script type="text/javascript" src="http://html5.kaltura.org/js"></script> <script type="text/javascript">

mw.setConfig('EmbedPlayer.AttributionButton',false);

mw.setConfig('EmbedPlayer.EnableOptionsMenu',false);

</script> <object name="ttvplayer" id="ttvplayer" type="application/x-shockwave-flash" allowScriptAccess="always" allowNetworking="all" allowFullScreen="true" height="336" width="544" data="http://www.kaltura.com/index.php/kwidget/wid/_203822/uiconf_id/1898102/entry_id/1_i5yndloo/"><param name="allowScriptAccess" value="always" /><param name="allowNetworking" value="all" /><param name="allowFullScreen" value="true" /><param name="bgcolor" value="#000000" /><param name="movie" value="http://www.kaltura.com/index.php/kwidget/wid/_203822/uiconf_id/1898102/entry_id/1_i5yndloo/"/><param name="flashVars" value="autoPlay=false&streamerType=rtmp"/><a href="http://ttv.mit.edu">MIT Tech TV</a></object> </html>

Calibration

Measuring R by scanning a stuck bead

PSD method

Equipartition method

Stokes method

<html> <script type="text/javascript" src="http://html5.kaltura.org/js"></script> <script type="text/javascript">

mw.setConfig('EmbedPlayer.AttributionButton',false);

mw.setConfig('EmbedPlayer.EnableOptionsMenu',false);

</script> <object name="ttvplayer" id="ttvplayer" type="application/x-shockwave-flash" allowScriptAccess="always" allowNetworking="all" allowFullScreen="true" height="336" width="544" data="http://www.kaltura.com/index.php/kwidget/wid/_203822/uiconf_id/1898102/entry_id/1_vzh3tc1f/"><param name="allowScriptAccess" value="always" /><param name="allowNetworking" value="all" /><param name="allowFullScreen" value="true" /><param name="bgcolor" value="#000000" /><param name="movie" value="http://www.kaltura.com/index.php/kwidget/wid/_203822/uiconf_id/1898102/entry_id/1_vzh3tc1f/"/><param name="flashVars" value="autoPlay=false&streamerType=rtmp"/><a href="http://ttv.mit.edu">MIT Tech TV</a></object> </html>